Achieve Unmatched Accuracy with Our Advanced Mechanical Load Testing Solutions

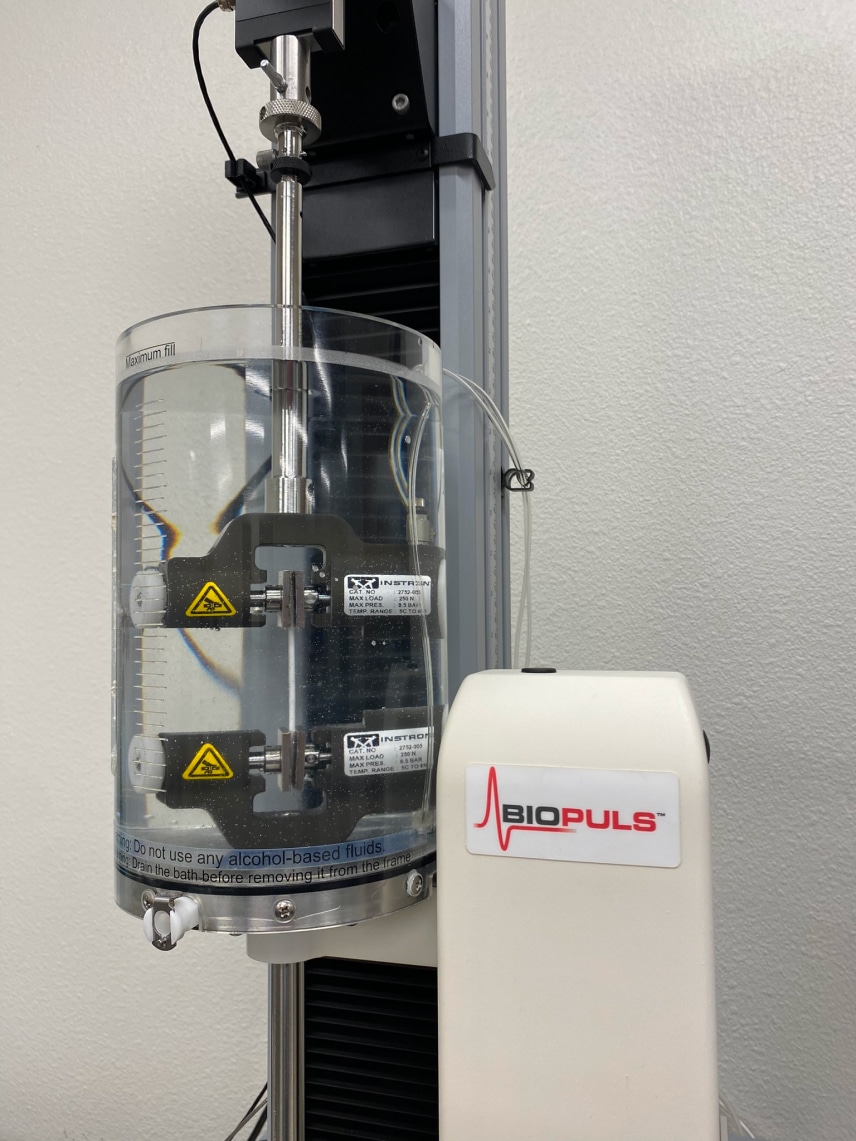

Empowering your research with precise force and material testing capabilities, our Instron testing machine ensures reliable results

delivering outstanding results for clients since 2001

Applications

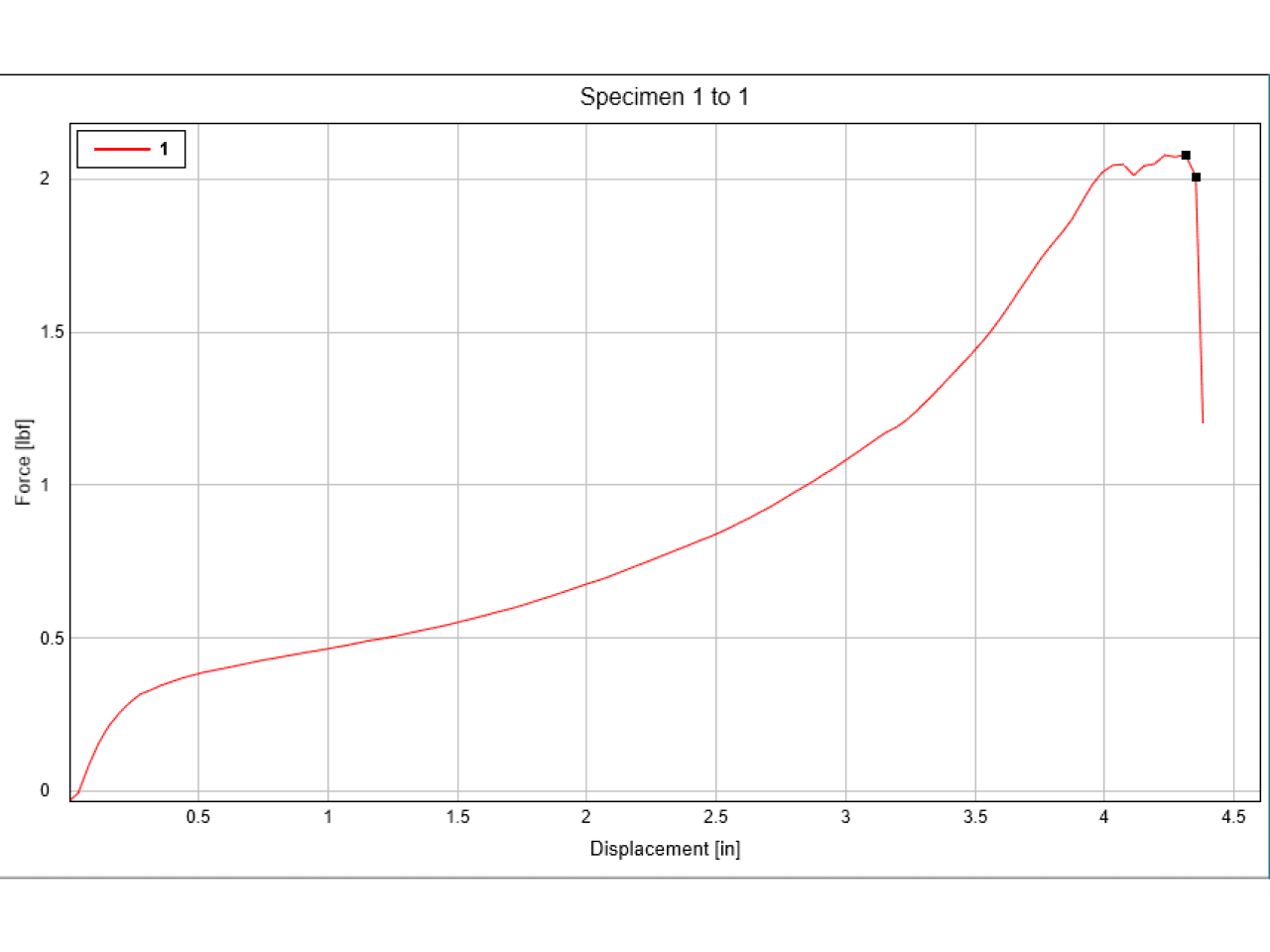

In Situ Tensile Tests

Conduct real-time tensile testing under controlled environments for precise, application-specific insights.

Polymers

Evaluate the strength and durability of polymers to ensure performance in various biomedical applications.

Catheters and Tubing

Determine how properties of catheters change through drug interactions, aging, or evaluate per ISO 10555.

Fabrics

Assess tensile and fatigue properties in biomedical fabrics for reliability and comfort in medical textiles.

Elastomers

Measure the flexibility and resistance of elastomers, essential for durable, flexible biomedical components..

Foams

Determine the compression and tensile strength of foams to ensure optimal cushioning and support in medical devices.

Adhesives and Joints

Test adhesion strength and joint strength for critical biomedical applications requiring secure bonding

Films

Analyze thin films for tensile strength and resistance to tearing, ensuring reliability in sensitive applications.

Custom Tests

Tailor tests to specific project needs, providing customized solutions for unique material testing challenges.

Comprehensive Instron Applications Tailored to Biomedical Device

Testing Needs

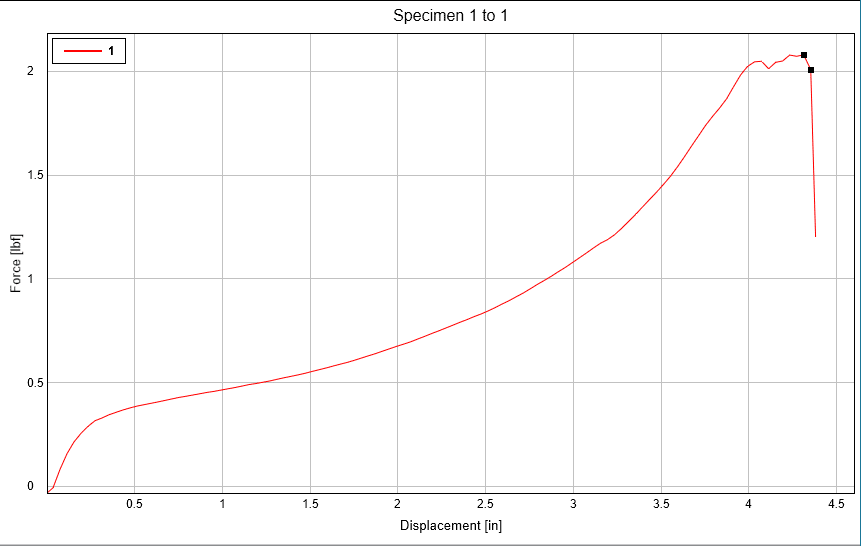

Our advanced Instron machine supports a wide range of biomedical testing applications, from tensile and compression testing to fatigue and fracture analysis. Designed to deliver accurate and reliable results, our Instron technology enables researchers and manufacturers to evaluate material properties with precision.

Capabilities

Precision Capabilities for Comprehensive Testing

Our Instron machine is engineered with advanced capabilities to support a wide range of material testing needs. From precise tensile and compression measurements to real-time in situ testing, our system delivers accurate, reliable results for polymers, rubbers, fabrics, and more.

- Tensile or Compression tests up to 1kN

- Tensile tests submerged in water or saline from 5-65 °C

- 41 inches of vertical testing space

Testimonials

Bausch + Lomb

“InVision does an excellent job throughout the testing process, starting with early project discussions, generating detailed and efficient protocols, excellent data collection, and finally great report writing with a comprehensive review process.”

OnPointVision

“Reports are very thorough. Questions I’ve asked have been satisfactorily responded to. They provide feedback on the results and any concerns with the test results. I always have confidence in the testing and reports InVision does for us.”

EyeDeal

“InVsion provided us with well thought out protocols according to our material characteristics and communicated thoroughly about the methods and conditions. We really appreciate your help.”

Zeiss

“The ISO standards 11979-2 and 11979-3 were understood well and the tests were executed accordingly. The communication was clear, concise, and fast.”

Testimonials

Feedback from Our Partners in Discovery

Bausch + Lomb

“InVision does an excellent job throughout the testing process, starting with early project discussions, generating detailed and efficient protocols, excellent data collection, and finally great report writing with a comprehensive review process.”

OnPointVision

“Reports are very thorough. Questions I’ve asked have been satisfactorily responded to. They provide feedback on the results and any concerns with the test results. I always have confidence in the testing and reports InVision does for us.”

EyeDeal

“InVsion provided us with well thought out protocols according to our material characteristics and communicated thoroughly about the methods and conditions. We really appreciate your help.”

Zeiss

“The ISO standards 11979-2 and 11979-3 were understood well and the tests were executed accordingly. The communication was clear, concise, and fast.”

Preview

FAQ

Your Questions Answered

What types of materials can the Instron machine test?

The Instron machine is designed to test a wide range of materials, including polymers, rubbers, fabrics, elastomers, foams, adhesives, seals, and films. Its versatility makes it ideal for diverse biomedical applications.

What specific tests can be performed with the Instron machine?

Our Instron machine can conduct tensile, fatigue, and compression tests, as well as in situ testing under controlled environments. It is also highly adaptable, allowing for customized tests to meet unique project requirements.

How accurate are the measurements from the Instron machine?

The Instron machine delivers high-precision results, offering reliable data on material strength, elasticity, and durability. This precision supports critical decision-making in quality control, product development, and research.

Can the Instron machine perform tests in physiological conditions?

Yes, the Instron machine offers in situ tensile testing, enabling real-time observation and analysis of material behavior under specific conditions, which is especially valuable for materials used in dynamic biomedical environments.

Is it possible to customize tests on the Instron machine?

Absolutely. The Instron machine allows for extensive customization, enabling tailored testing protocols for specialized materials and unique project needs. This flexibility ensures that testing aligns with your specific research objectives.