See Beyond the Surface with our High-Resolution

SEM Technology

Whether you're conducting in-depth research or intricate material analysis, our SEM empowers you to see beyond the surface.

delivering outstanding results for clients since 2001

Applications

Comprehensive SEM Applications Tailored to Biomedical Needs.

Invision Biomedical’s SEM technology supports a broad spectrum of specialized applications designed for advanced biomedical research and quality assurance. Whether you’re advancing nanotechnology research or seeking customized solutions, our SEM technology delivers the precision and versatility to meet your unique requirements.

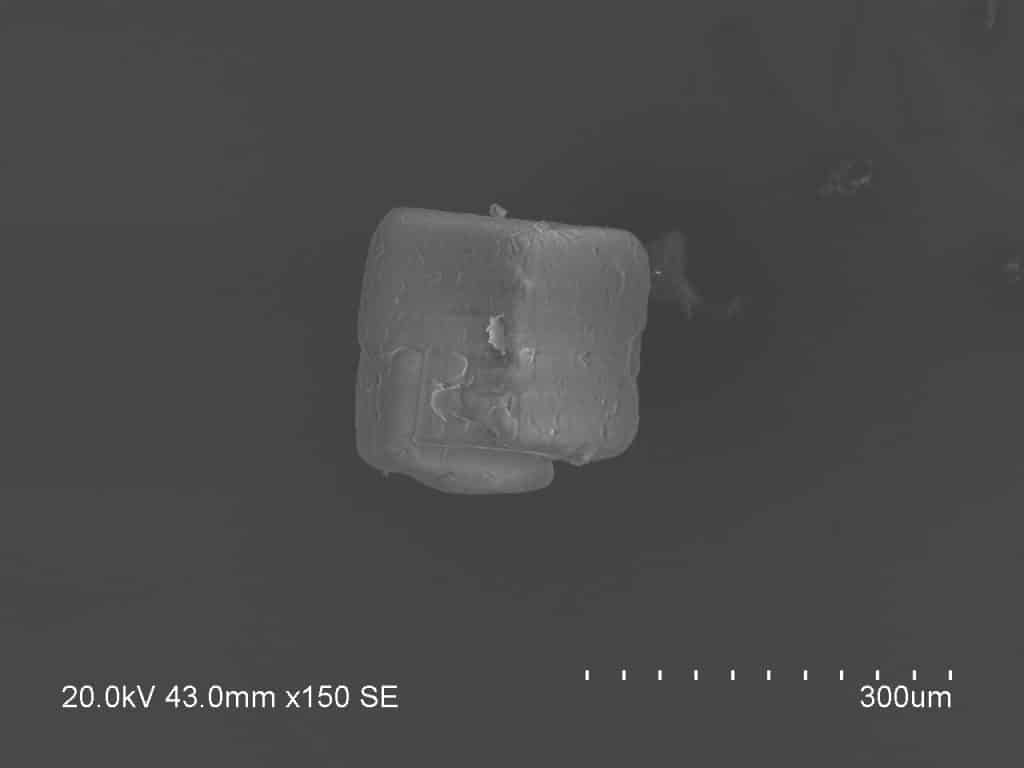

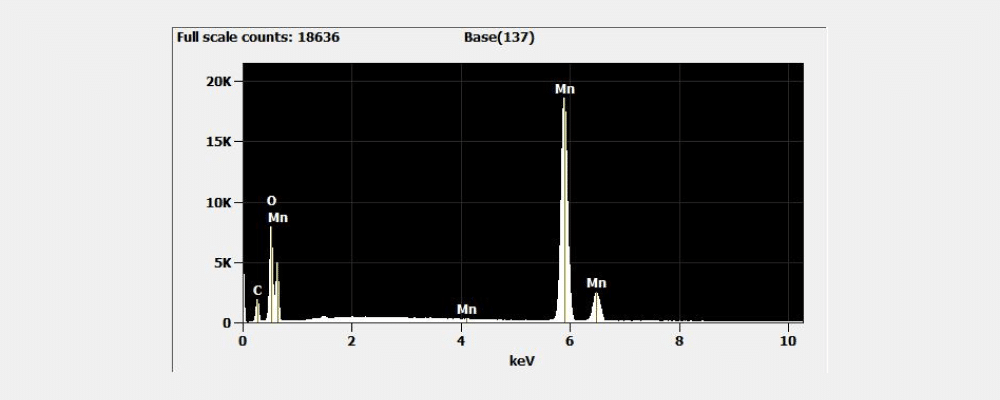

Surface Contaminant Analysis

Detect and analyze surface contaminants with precision to ensure the highest standards of cleanliness and integrity in biomedical materials.

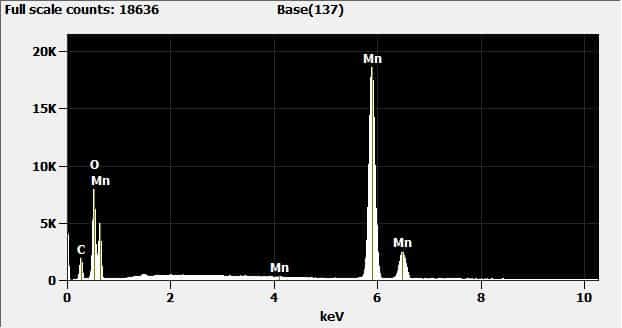

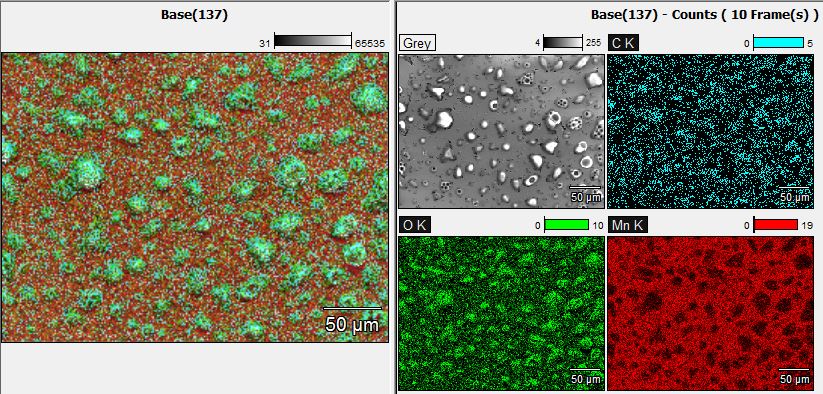

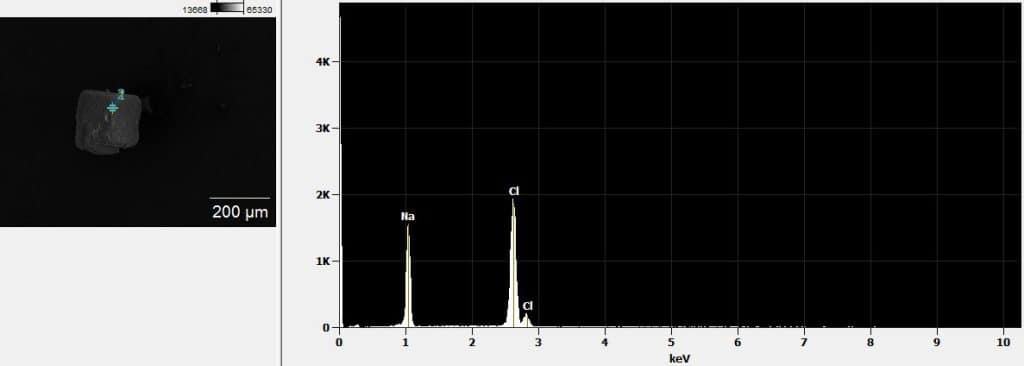

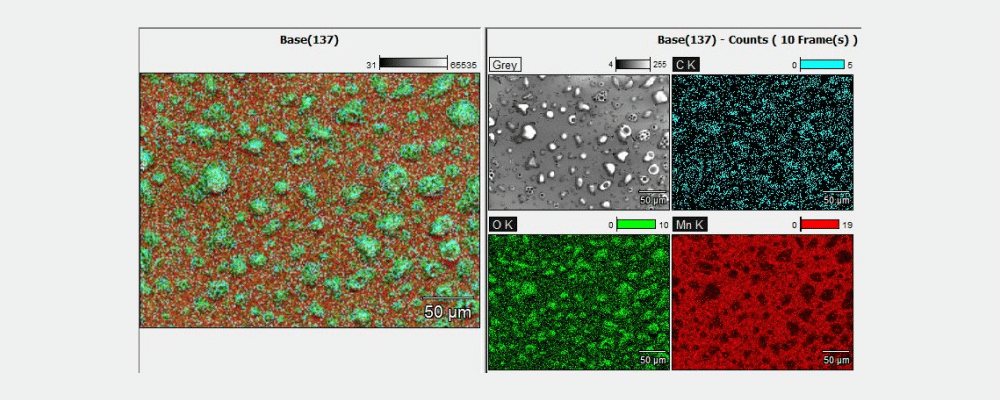

Elemental Identification with EDS

Identify elemental compositions quickly and accurately using Energy Dispersive Spectroscopy (EDS), essential for comprehensive analysis.

Fracture Analysis

Investigate fracture mechanisms to enhance durability and reliability in product development and failure prevention.

Corrosion Analysis

Assess and understand corrosion patterns to improve material resilience and extend the lifecycle of biomedical components.

Stability and Aging Studies

Conduct stability testing according to ISO standards such as 11979-5, crucial for ensuring compliance and product safety in implantable devices

Dimensional Analysis

Achieve precise measurements at the microscopic level, supporting exact specifications for manufacturing and research.

Manufacturing Quality Control

Implement rigorous quality checks with SEM analysis to maintain production consistency and meet industry standards.

Nanotechnology Research

Explore nanoscale structures in biomedical materials, advancing innovations in treatment and diagnostics.

Custom Services

Tailor SEM analysis to fit unique project needs, offering specialized insights and flexible solutions for specific research goals.

Capabilities

Advanced Capabilities for Precision and Versatility

Our state-of-the-art SEM machine is designed to provide unparalleled flexibility and accuracy for a range of applications.

- 5 axis sample stage

- Environmental Variable Pressure mode

- Samples up to 80mm tall & 200mm diameter

- Resolution up to 3.0nm

- Identify elements as light as Beryllium

- Compositional Distribution Mapping

Testimonials

Bausch + Lomb

“InVision does an excellent job throughout the testing process, starting with early project discussions, generating detailed and efficient protocols, excellent data collection, and finally great report writing with a comprehensive review process.”

OnPointVision

“Reports are very thorough. Questions I’ve asked have been satisfactorily responded to. They provide feedback on the results and any concerns with the test results. I always have confidence in the testing and reports InVision does for us.”

EyeDeal

“InVsion provided us with well thought out protocols according to our material characteristics and communicated thoroughly about the methods and conditions. We really appreciate your help.”

Zeiss

“The ISO standards 11979-2 and 11979-3 were understood well and the tests were executed accordingly. The communication was clear, concise, and fast.”

Testimonials

Feedback from Our Partners in Discovery

Bausch + Lomb

“InVision does an excellent job throughout the testing process, starting with early project discussions, generating detailed and efficient protocols, excellent data collection, and finally great report writing with a comprehensive review process.”

OnPointVision

“Reports are very thorough. Questions I’ve asked have been satisfactorily responded to. They provide feedback on the results and any concerns with the test results. I always have confidence in the testing and reports InVision does for us.”

EyeDeal

“InVsion provided us with well thought out protocols according to our material characteristics and communicated thoroughly about the methods and conditions. We really appreciate your help.”

Zeiss

“The ISO standards 11979-2 and 11979-3 were understood well and the tests were executed accordingly. The communication was clear, concise, and fast.”

Preview

FAQ

Your Questions Answered

What is a Scanning Electron Microscope (SEM) and how does it work?

A Scanning Electron Microscope (SEM) is an advanced imaging tool that uses focused beams of electrons to create high-resolution images of a sample’s surface. Unlike traditional microscopes, SEM provides exceptional detail at the microscopic level, making it ideal for examining fine surface structures, material composition, and other crucial properties.

What kind of samples can be analyzed with Invision Biomedical’s SEM?

Our SEM is highly versatile and can analyze a wide range of samples, including metals, polymers, biological tissues, and nanomaterials. It’s designed to accommodate various biomedical and industrial applications, offering flexibility to meet diverse research and quality control needs.

What is Elemental Dispersive Spectroscopy (EDS) and how does it enhance SEM analysis?

EDS is an add-on technique used alongside SEM to determine the elemental composition of a sample. By analyzing the energy and wavelengths of X-rays emitted from the sample, EDS identifies the elements present, enabling precise compositional analysis, especially useful in material science and quality control.

How does SEM support quality control in manufacturing?

SEM can identify and quantify surface contaminants, measure fine structural dimensions, and ensure that manufactured components meet rigorous standards. This makes it an essential tool for maintaining consistent quality, particularly in industries that require high-precision components, such as biomedical devices.

How can I request custom SEM services for my specific project needs?

SEM can identify and quantify surface contaminants, measure fine structural dimensions, and ensure that manufactured components meet rigorous standards. This makes it an essential tool for maintaining consistent quality, particularly in industries that require high-precision components, such as biomedical devices.